Mon 06 December 2004 |

| After some of the frustration from yesterday, I started this morning with some 'therapy'.

Edge smoothing and preparation for some parts I will need in the future. I've found on a number of occasions that doing the basic processes allows time to relax a bit and step back from the problems at hand whilst still progressing the overall project forward as it has to be completed at some point anyway. It is also really good to pick up a 'new' part and find it already prepared and that in turn accelerates the assembly process. |

|

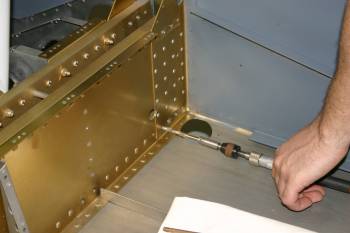

| Dad mean time was still struggling with the lower 1/4" main spar bolts. Again the plate alignment was out and the shop bolts weren't even starting to go through. More careful reamer work, slowly and only where absolutely needed. |

|

| I then started on the front wing / fuel tank attach bracket. This first required drilling out some rivets (which shouldn't have been set) just behind the leading edge of the wing. |

|

| The edge distances for the shims and strengthener inside the fuselage are very tight and I ended up making the two sheet shims slightly longer to easy the upper edge clearance. |

|

| The other issue we have is the QuickBuild guys have fluted and dimpled the skin / bulkhead which makes getting the internal stiffener / shims to lay flat very difficult. |

|

| Then it was on to parts fabrication. Normal drill - first understand the drawings, then make a couple of 'proto-types'. The 3rd and 4th attempts are fine....... The key here was the strange angles and exact lengths of the AL angle. It does work and the edge distances are OK, but very tight. |

|

| Dad also super-glued the washer / spacer to the right location for the gear leg weldment. Otherwise this is a real XXXX to get inserted and lined up. |

|

| The final part of the day I sorted the match drilling of the bracket / shims and skin. Both sides are now ready to be opened up for AN3 bolts and match drilled for the external tank bracket. |

|