Mon 13 February 2006 |

| Dad match drilled the aft cover plates, we had to remove them from the QB fuselage to get to the step mounts sorted. |

|

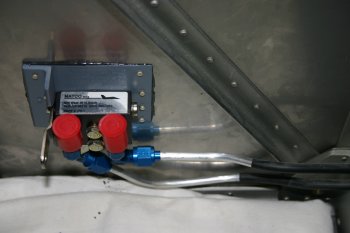

| I bucked the brake valve plate and did the brake lines up finger tight. |

|

| Dad continued with the spar and snap bushes. |

|

| At this point we stuck with 5/8" holes, although the position will let us open them up further if needed. |

|

| Meanwhile I continued with the cowl inlets, this time laying up some 2 & 6 oz strips around the top and lower rear surface. This should hopefully strengthen the tubes without adding to much weight. |

|

| A single front surface layer was also added and then trimmed back. |

|

| Then onto some sanding (for a change!). The elevators still needed the counter balance to be sorted, palm sander worked well. |

|

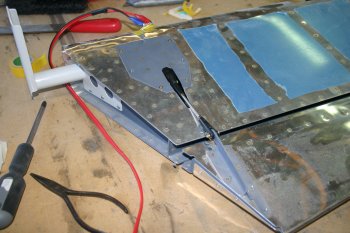

| A bit job that has been on the list for a little while was the elevator trim push rod. I could find no dimensions / drawings detailing lengths so went with the mark one eyeball. One note, the servo end has to be connected before it is put into the elevator - otherwise there isn't any access. |

|

| Before I quit for the night, I trimmed with a knife the RHS inlet glass-plys, the LHS wasn't cured. |

|